Heat treated timber

Technology

High Temperature Treatment is a 100% natural process that modifies the physical and aesthetic characteristics of wood without the use of any synthetic product.

HHT or heat treated wood opens new horizons in terms of applications and creations!

There

is a wider range of colours, providing a greater and more nuanced pallet.

There’s ample species for outdoor use too. In fact, this process makes it

possible to develop local species and to use ash or poplar, for example,

outside with no harmful results.

Without a doubt, HTT wood inspires architects, landscape gardeners and urban designers by opening the realm of possibilities in areas of outdoor planning and design.

Namely: Don’t confuse high temperature treatment with autoclave treatment, which consists of introducing preservatives into the heart of the wood to reinforce its durability.

With HTT, the wood is made more durable, more stable and more resistant in three precise and controlled phases by high-tech equipment:

The temperature level

To achieve this new performance and new look, the wood is heated in an oven where the temperature increases rapidly up to 100°C with steam, then gradually increasing up to 130°C for complete drying. The duration of this step is adapted as a function of the species and the section of the treated timber.

Treatment by high temperature

It is when the temperature reaches 150°C that the properties of wood change. The temperature is then taken to between 160°C and 230°C for one to two hours in a stable manner as a function of the desired characteristics.

The cooling and re-humidification of the wood

To guarantee proper re-humidification of the wood, the temperature of the oven is lowered and steam is sprayed in. This causes a slight increase in moisture in the wood and a new short heating phase. This final step lasts between 5 and 15 hours depending on the desired properties.

Benefits

High temperature treatment gives wood remarkable properties:

- Better resistance to fungal attacks and to wood-eating insects.

- Better dimensional stability.

- Heat treated wood have a durability increased

- Moisture balance reduced by about 50%

- New natural and consistent colours resembling tropical woods

- Material 100% natural and easily recyclable

- Reduction of extractables (tannins, resin)

- Able to be glued and receive finishing products

- Thermal conductivity reduced by 10 to 30%

- Increased wood rigidity

- Reduction in tensile strength

- Density reduced by about 10%

INDOOR APPLICATIONS

Home furnishings

Tables, chairs, cabinets, glued laminated worktops, decorative panels, accent furniture, shelves

Indoor applications in humid environment

Sauna panelling, wet room layouts

Indoor layouts and joineries

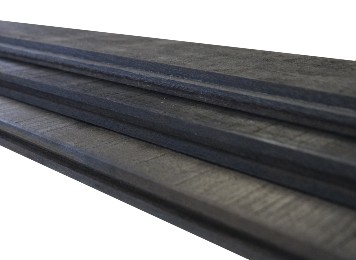

Boards, parquets, panelling, plinths, indoor profiles, all wood components joinery

OUTDOOR APPLICATIONS

Siding

Cladding

Clapboard, clerestory

Outdoor layout, garden equipment

Decking, gratings, pergolas, sheds, garden structures, planters, flower boxes, swimming pool borders and floors, fence posts and stakes

Outdoor layout

Frames, window components, shutters, blinds, fences, doors

Roadway uses

Marker boards, acoustic and motorway screens

Species available in THT wood

Our species are selected with the greatest care to guarantee a finished product of impeccable quality.

THT wood products

Products made from wood treated by high temperature open new horizons for applications.